- CNC Machining

- Stainless steel cnc machining parts

- customized metal board cnc parts

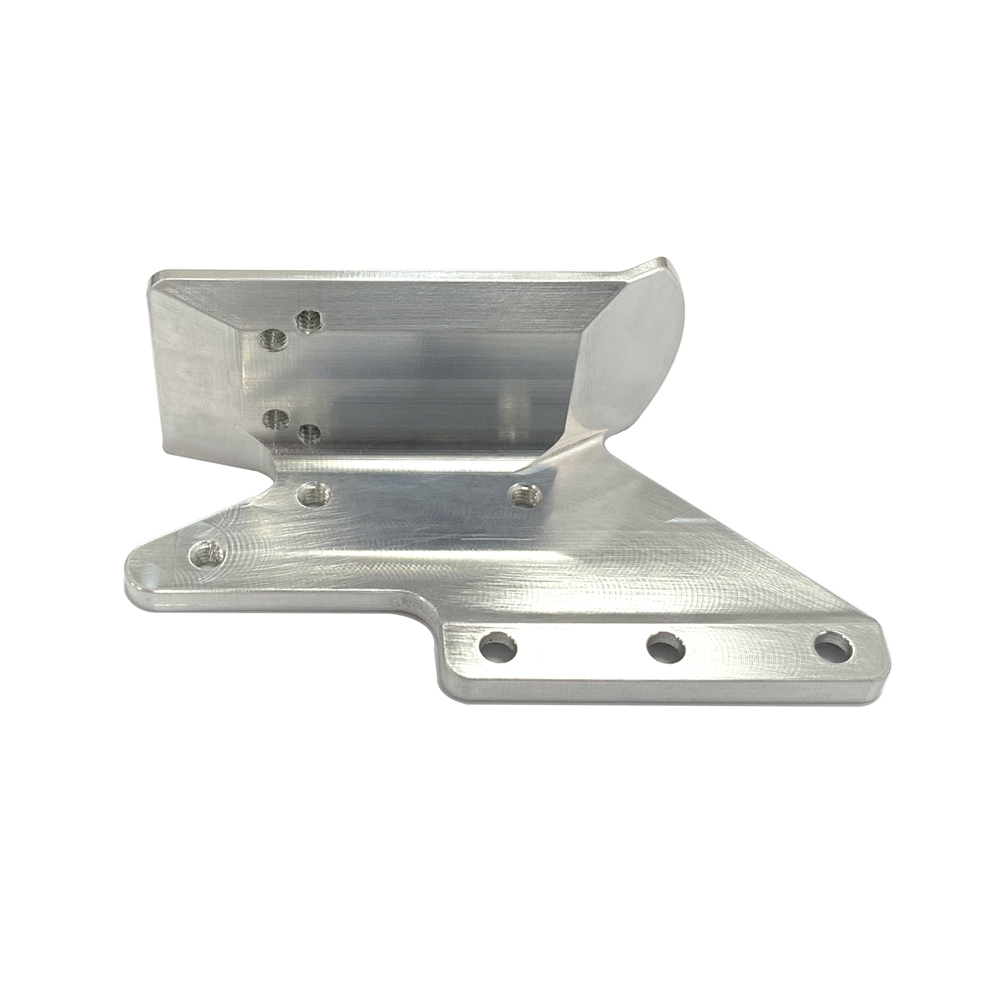

- electric motorcycle cnc milling turning metal parts

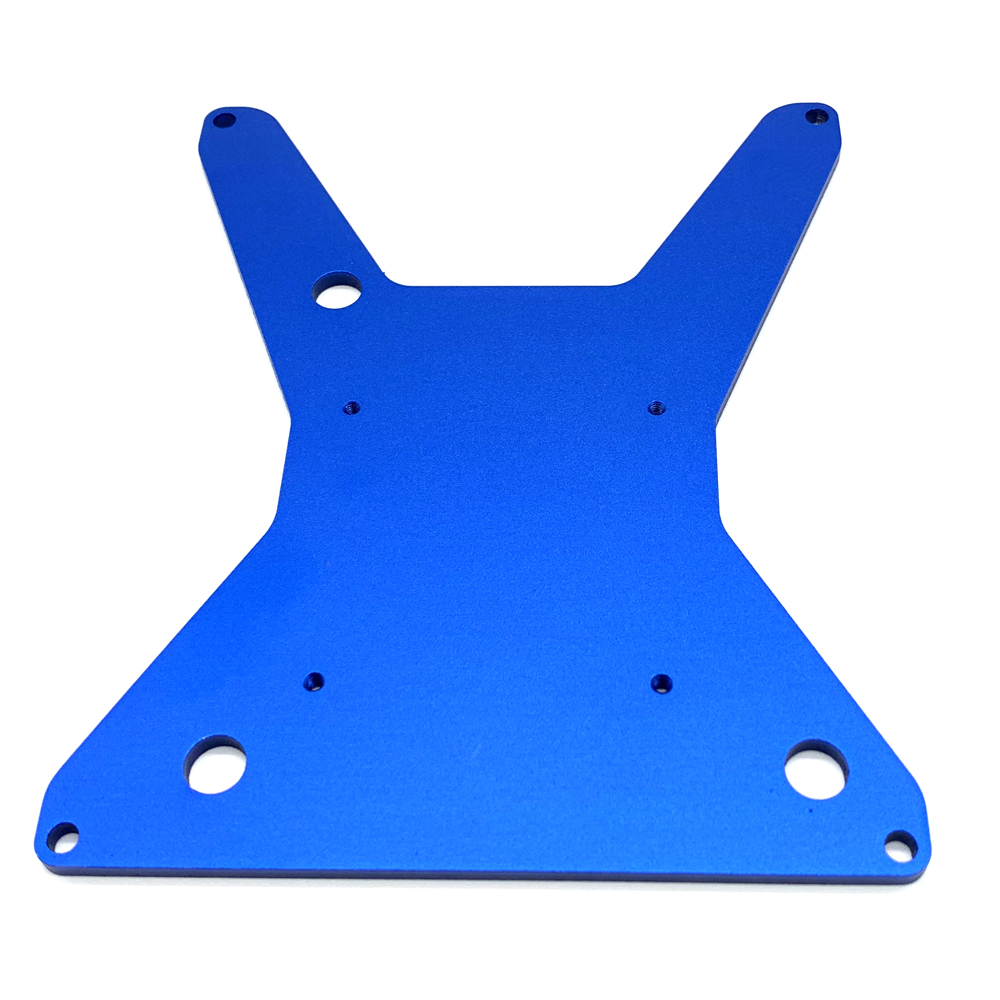

- Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories

- the head of custom spray gun

- CNC Machining Parts Manufacturer Stainless Steel Aluminum CNC Mechanical Parts

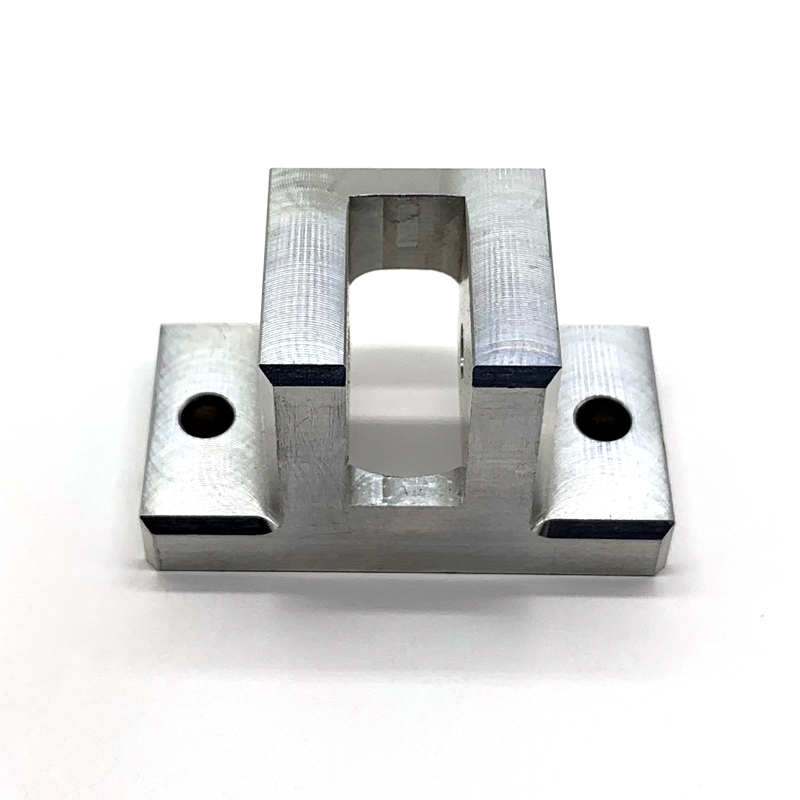

- cnc milling machining turning spare parts mechanical parts

- CNC Machining Precision Parts Full Shift Switch Invisible Switch

- CNC machining small aluminum machined metal wheel gear parts

-

Stainless steel cnc machining parts China Metal Parts Services - CNC Machining Parts Supplier

World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

Stainless steel cnc machining parts China Metal Parts Services - CNC Machining Parts Supplier

World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More -

customized metal board cnc parts OEM Custom Cnc Milling Turning Stainless Steel Aluminum Brass Metal Parts More

customized metal board cnc parts OEM Custom Cnc Milling Turning Stainless Steel Aluminum Brass Metal Parts More -

electric motorcycle cnc milling turning metal parts Custom CNC turning milling machining aluminum service More

electric motorcycle cnc milling turning metal parts Custom CNC turning milling machining aluminum service More

-

Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories More

Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories More -

the head of custom spray gun Custom CNC Machining Service Precision Titanium Brass Stainless Steel More

the head of custom spray gun Custom CNC Machining Service Precision Titanium Brass Stainless Steel More -

CNC Machining Parts Manufacturer Stainless Steel Aluminum CNC Mechanical Parts Precision CNC Turning Steel Parts ,CNC Machine Part More

CNC Machining Parts Manufacturer Stainless Steel Aluminum CNC Mechanical Parts Precision CNC Turning Steel Parts ,CNC Machine Part More -

cnc milling machining turning spare parts mechanical parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

cnc milling machining turning spare parts mechanical parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More -

CNC Machining Precision Parts Full Shift Switch Invisible Switch China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

CNC Machining Precision Parts Full Shift Switch Invisible Switch China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More -

CNC machining small aluminum machined metal wheel gear parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

CNC machining small aluminum machined metal wheel gear parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

-

the customized metal parts of toy model car wheel hub we are specialized in prodicing all kinds of metal parts applying to building Material Shops, Manufacturing plant, and so forth so on More

the customized metal parts of toy model car wheel hub we are specialized in prodicing all kinds of metal parts applying to building Material Shops, Manufacturing plant, and so forth so on More -

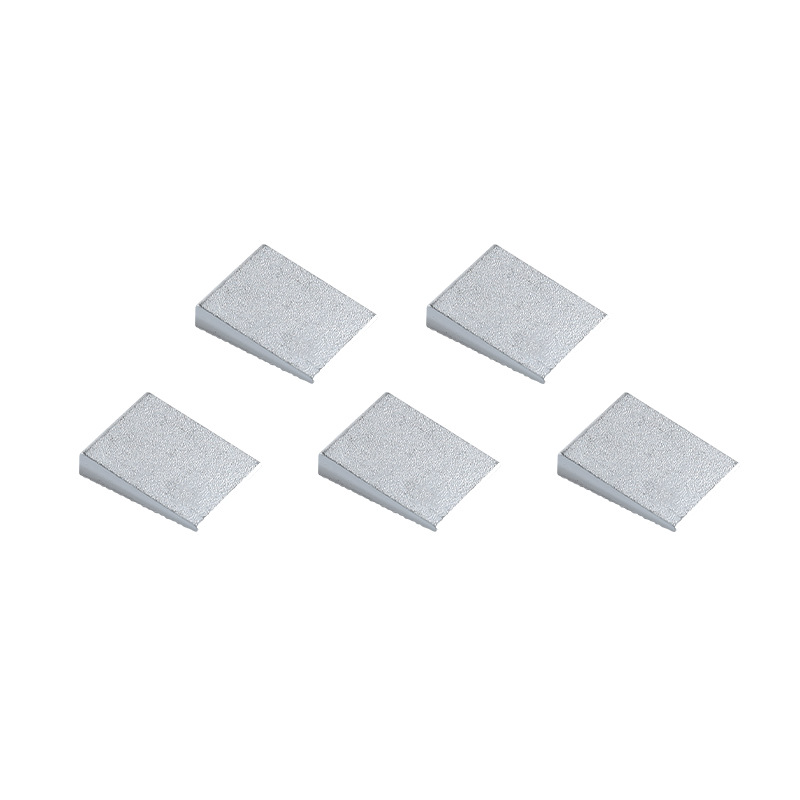

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service We provide CNC drilling services that can process small and large batches of components of any complexity. We use different types of drilling machines (vertical, bench, radial) to drill holes with a diameter of up to 7 centimeters, and can achieve simple or complex patterns. This manufacturing method is applicable to metals and alloys (aluminum, steel, copper, etc.) and polymers More

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service We provide CNC drilling services that can process small and large batches of components of any complexity. We use different types of drilling machines (vertical, bench, radial) to drill holes with a diameter of up to 7 centimeters, and can achieve simple or complex patterns. This manufacturing method is applicable to metals and alloys (aluminum, steel, copper, etc.) and polymers More -

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service china manufacturer professional made precision profile aluminum swiss machining cnc drilling parts More

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service china manufacturer professional made precision profile aluminum swiss machining cnc drilling parts More

-

Customized Pen Shell we provide CNC machining service,just sending us a drawing for quote. More

Customized Pen Shell we provide CNC machining service,just sending us a drawing for quote. More -

the shell of portable battery ,the customized metal housing sent us the drawings and we give you a appropriate quote More

the shell of portable battery ,the customized metal housing sent us the drawings and we give you a appropriate quote More -

the metal cap of pen ,none-standard cap we are chinese manufacturer ,we provide competetive price.we can produce CNC parts and make a polishing. More

the metal cap of pen ,none-standard cap we are chinese manufacturer ,we provide competetive price.we can produce CNC parts and make a polishing. More

- CNC Solution

- What principles should be followed in the arrangement of CNC machining sequence?

- Technology Application For CNC

- Basic composition of CNC lathe

- Selection principles for CNC

- The Fetures Of CNC

- CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES

- CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES

- CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES

- CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES

- CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES

- CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES

-

What principles should be followed in the arrangement of CNC machining sequence? More

What principles should be followed in the arrangement of CNC machining sequence? More -

Technology Application For CNC More

Technology Application For CNC More -

Basic composition of CNC lathe More

Basic composition of CNC lathe More -

Selection principles for CNC More

Selection principles for CNC More -

The Fetures Of CNC More

The Fetures Of CNC More -

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More -

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More -

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More -

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More -

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More -

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

- Metal Project

- News

- About

- Contact