A CNC lathe is composed of a CNC device, bed, spindle box, tool holder feed system, tailstock, hydraulic system, cooling system, lubrication system, chip conveyor, and other parts.

CNC lathes are divided into two types: vertical CNC lathes and horizontal CNC lathes.

Vertical CNC lathes are used for turning large diameter disc parts.

Horizontal CNC lathes are used for turning long or small disc parts with axial dimensions.

Horizontal CNC lathes can be further divided into economic CNC lathes, ordinary CNC lathes, and turning machining centers based on their functions.

Economical CNC lathe: A simple CNC lathe formed by modifying the turning feed system of a regular lathe with a stepper motor and a microcontroller. The cost is relatively low, the degree of automation and functionality are relatively poor, and the turning accuracy is also not high. It is suitable for turning rotary parts with low requirements.

Ordinary CNC lathe: A CNC lathe that is specially designed in structure according to the requirements of turning processing and equipped with a universal CNC system. The CNC system has strong functions, high automation and machining accuracy, and is suitable for turning general rotary parts. This CNC lathe can simultaneously control two coordinate axes, namely the x-axis and z-axis.

turning center

Turning machining center: On the basis of ordinary CNC lathes, a C-axis and power head have been added. More advanced machine tools also have a tool magazine, which can control the X, Z, and C coordinate axes. The linkage control axes can be (X, Z), (X, C), or (Z, C). Due to the addition of the C-axis and milling power head, the machining function of this CNC lathe is greatly enhanced. In addition to general turning, it can also perform radial and axial milling, curved surface milling, drilling of holes with centerlines not in the center of rotation of the parts, and drilling of radial holes.

Hydraulic chuck and hydraulic tailstock

Hydraulic chuck is an important accessory for clamping workpieces during CNC turning, and ordinary hydraulic chuck can be used for general rotary parts; For parts that are not cylindrical in shape, special chucks are required; Spring chucks are required when directly processing parts with bar stock. For parts with a large ratio of axial and radial dimensions, it is necessary to use a movable center installed on the hydraulic tailstock to support the tail end of the parts in order to ensure correct machining of the parts. There are regular hydraulic tailstock and programmable hydraulic tailstock.

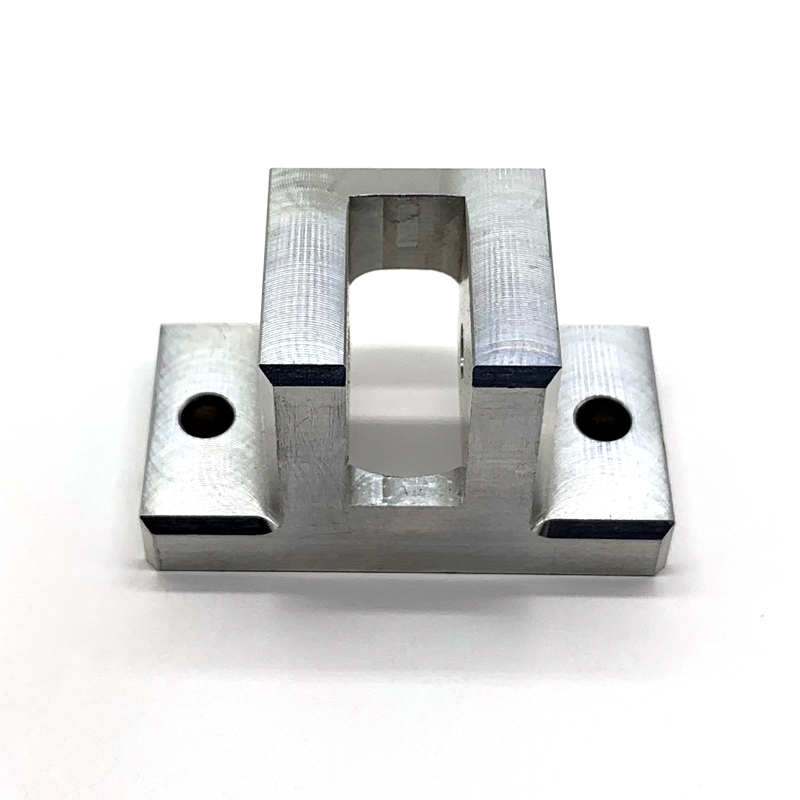

Universal tool holder

CNC lathes can be equipped with two types of tool holders:

① Special tool holder: Developed by the lathe manufacturer themselves, the tool holder used is also specialized. The advantage of this tool holder is its low manufacturing cost, but it lacks universality.

② Universal tool holder: A tool holder produced according to certain universal standards (such as VDI, German Association of Engineers), and CNC lathe manufacturers can choose and configure according to the functional requirements of CNC lathes.

Milling power head

The installation of milling power head on the CNC lathe tool holder can greatly expand the machining capacity of the CNC lathe. For example, using a milling power head for axial drilling and milling of axial grooves.

Cutting tools for CNC lathes

When turning parts on a CNC lathe or turning machining center, the position of the tool on the tool holder should be reasonably and scientifically arranged based on the structure of the lathe tool holder and the number of tools that can be installed. Attention should be paid to avoiding interference between the tool and the machine tool, tool and workpiece, and tool interaction when the tool is stationary and working.

Machine tool composition

The host is the main body of a CNC machine tool, including mechanical components such as the machine body, column, spindle, and feed mechanism. He is a mechanical component used to complete various cutting processes.

CNC equipment is the core of CNC machine tools, including hardware (printed circuit boards, CRT displays, keyboxes, paper tape readers, etc.) and corresponding software, used to input digital part programs, and complete the storage of input information, data transformation, interpolation operations, and implementation of various control functions.

The drive device is the driving component of the execution mechanism of a CNC machine tool, including the spindle drive unit, feed unit, spindle motor, and feed motor. He achieves spindle and feed drive through an electrical or electro-hydraulic servo system under the control of a CNC device. When several feeds are linked, the machining of positioning, straight line, plane curve and space curve can be completed.

Auxiliary devices are necessary supporting components of index controlled machine tools to ensure the operation of CNC machine tools, such as cooling, chip removal, lubrication, lighting, monitoring, etc. It includes hydraulic and pneumatic devices, chip removal devices, exchange workbenches, CNC turntables and CNC indexing heads, as well as cutting tools and monitoring and detection devices.

Programming and other auxiliary equipment can be used to program and store parts outside the machine.

Since the development of the world's first CNC machine tool by the Massachusetts Institute of Technology in 1952, CNC machine tools have been widely used in the manufacturing industry, especially in automobiles, aerospace, and military industries. CNC technology has developed rapidly in both hardware and software.

Stainless steel cnc machining parts China Metal Parts Services - CNC Machining Parts Supplier

World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

Stainless steel cnc machining parts China Metal Parts Services - CNC Machining Parts Supplier

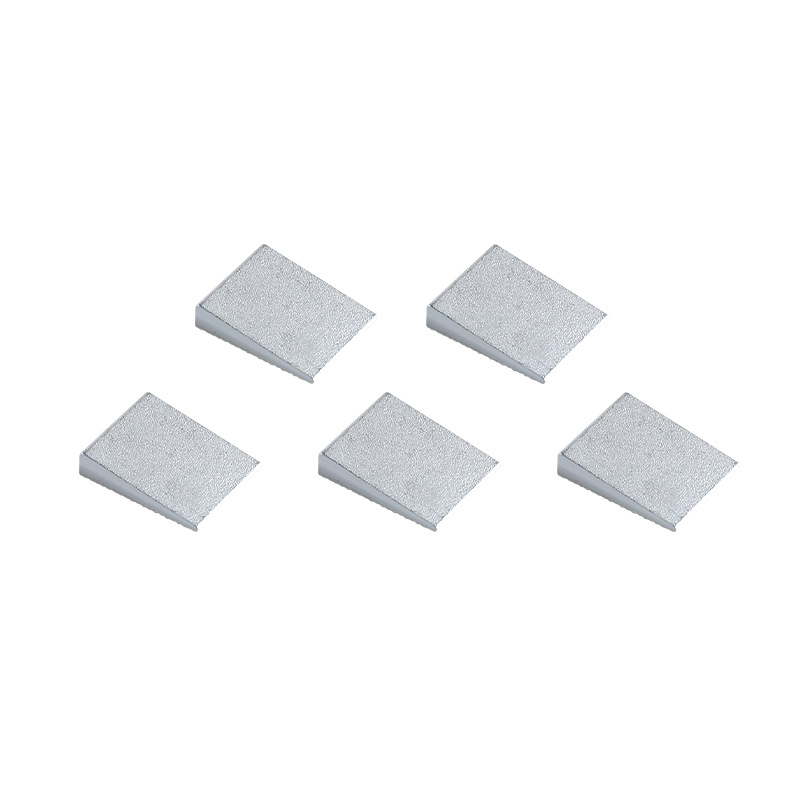

World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  customized metal board cnc parts OEM Custom Cnc Milling Turning Stainless Steel Aluminum Brass Metal Parts More

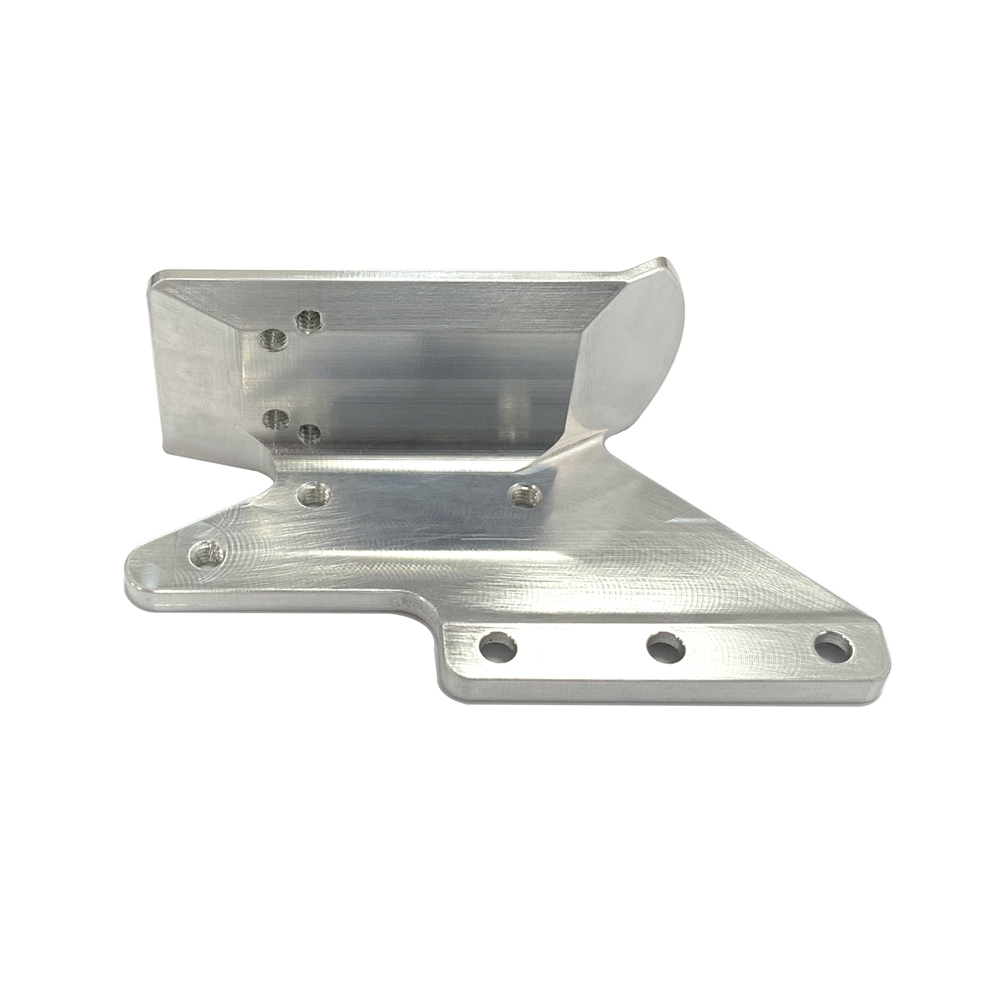

customized metal board cnc parts OEM Custom Cnc Milling Turning Stainless Steel Aluminum Brass Metal Parts More  electric motorcycle cnc milling turning metal parts Custom CNC turning milling machining aluminum service More

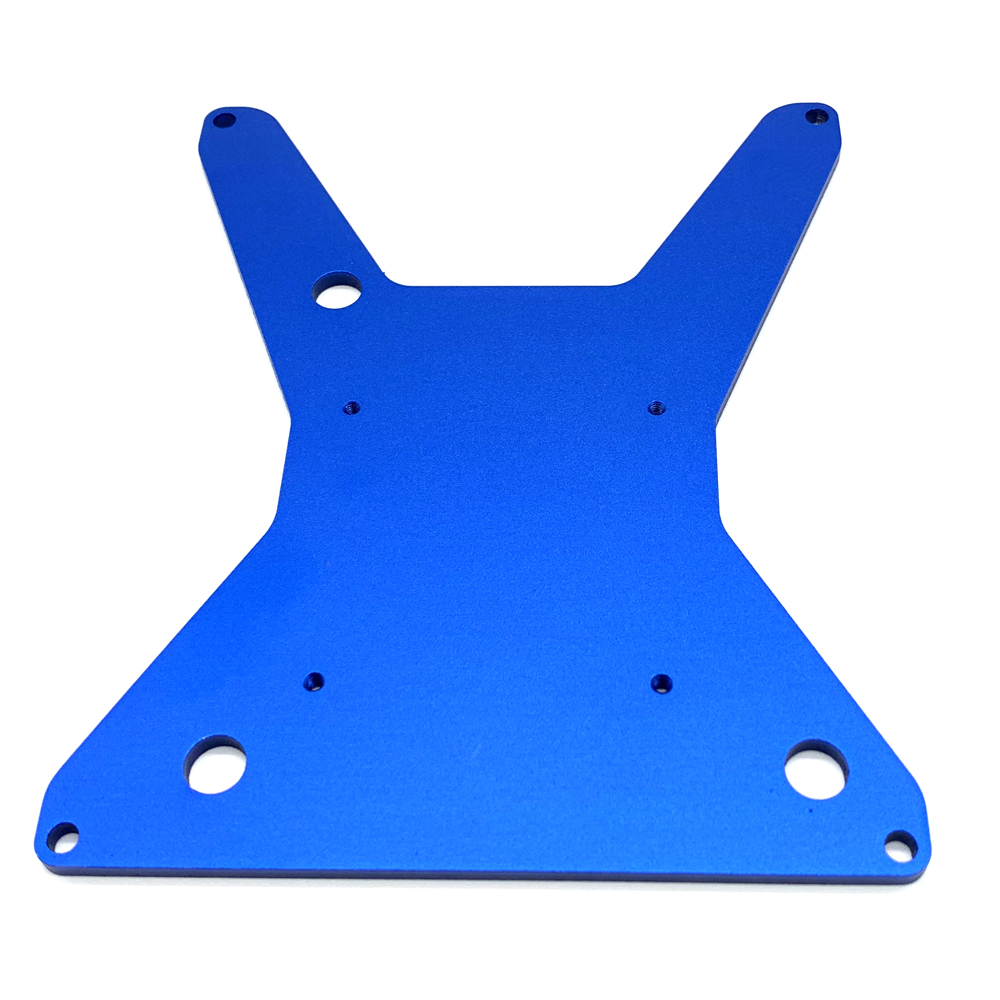

electric motorcycle cnc milling turning metal parts Custom CNC turning milling machining aluminum service More  Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories More

Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories More  the head of custom spray gun Custom CNC Machining Service Precision Titanium Brass Stainless Steel More

the head of custom spray gun Custom CNC Machining Service Precision Titanium Brass Stainless Steel More  CNC Machining Parts Manufacturer Stainless Steel Aluminum CNC Mechanical Parts Precision CNC Turning Steel Parts ,CNC Machine Part More

CNC Machining Parts Manufacturer Stainless Steel Aluminum CNC Mechanical Parts Precision CNC Turning Steel Parts ,CNC Machine Part More  cnc milling machining turning spare parts mechanical parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

cnc milling machining turning spare parts mechanical parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  CNC Machining Precision Parts Full Shift Switch Invisible Switch China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

CNC Machining Precision Parts Full Shift Switch Invisible Switch China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  CNC machining small aluminum machined metal wheel gear parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

CNC machining small aluminum machined metal wheel gear parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  the customized metal parts of toy model car wheel hub we are specialized in prodicing all kinds of metal parts applying to building Material Shops, Manufacturing plant, and so forth so on More

the customized metal parts of toy model car wheel hub we are specialized in prodicing all kinds of metal parts applying to building Material Shops, Manufacturing plant, and so forth so on More  High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service We provide CNC drilling services that can process small and large batches of components of any complexity. We use different types of drilling machines (vertical, bench, radial) to drill holes with a diameter of up to 7 centimeters, and can achieve simple or complex patterns. This manufacturing method is applicable to metals and alloys (aluminum, steel, copper, etc.) and polymers More

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service We provide CNC drilling services that can process small and large batches of components of any complexity. We use different types of drilling machines (vertical, bench, radial) to drill holes with a diameter of up to 7 centimeters, and can achieve simple or complex patterns. This manufacturing method is applicable to metals and alloys (aluminum, steel, copper, etc.) and polymers More  High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service china manufacturer professional made precision profile aluminum swiss machining cnc drilling parts More

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service china manufacturer professional made precision profile aluminum swiss machining cnc drilling parts More  Customized Pen Shell we provide CNC machining service,just sending us a drawing for quote. More

Customized Pen Shell we provide CNC machining service,just sending us a drawing for quote. More  the shell of portable battery ,the customized metal housing sent us the drawings and we give you a appropriate quote More

the shell of portable battery ,the customized metal housing sent us the drawings and we give you a appropriate quote More  the metal cap of pen ,none-standard cap we are chinese manufacturer ,we provide competetive price.we can produce CNC parts and make a polishing. More

the metal cap of pen ,none-standard cap we are chinese manufacturer ,we provide competetive price.we can produce CNC parts and make a polishing. More  What principles should be followed in the arrangement of CNC machining sequence? More

What principles should be followed in the arrangement of CNC machining sequence? More  Technology Application For CNC More

Technology Application For CNC More  Basic composition of CNC lathe More

Basic composition of CNC lathe More  Selection principles for CNC More

Selection principles for CNC More  The Fetures Of CNC More

The Fetures Of CNC More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More