The W11 CNC machine tool is mainly designed for manufacturers who require single piece processing, prototype trial production, or small batch production. The new W11 CNC machine tool is an ideal equipment, providing users with many carefully designed operating aids. In addition, the highlight of this machine tool lies in its excellent operability, which can be operated through both an intuitive touch screen and a traditional button panel.

W11 CNC is a traditional universal circular grinding machine with a 2-in-1 design. This machine tool design is achieved through the use of modern CNC control systems. The CNC control system can be operated very easily and simply through the touch screen, thus reducing the tedious work of users and allowing them to fully focus on the processing of components.

Optimization through automation of various time-consuming processes

W11 CNC can achieve fully automatic trimming of diamond grinding wheels and workpieces, which means it can automatically trim various shapes such as radii, slopes, and cones. And it will also fully automatically compensate for the amount of trimming. In addition to trimming, the CNC control system also has multiple advantages: for example, it can automatically grind various workpieces of different diameters in one clamping process. In the path selection mode, it is even possible to grind cones and various profiles on the W11 CNC. This machine tool also has various comfort functions, such as automatically retracting the grinding wheel to a safe position for replacement, ensuring faster replacement time.

Modern and fast control unit designed for grinding

Like the entire machine tool, modern control systems are also aimed at optimizing the grinding process. Data input and system control can be completely achieved through the touch screen. The machine tool can be programmed through a dialogue interface or using DINISO. Due to the use of a Windows system throughout the entire software, it is possible to quickly exchange data with a desktop computer using a USB interface. This way, grinding programs can be directly written in the R&D department and quickly and easily transmitted to the machine tool. The standard software includes all commonly used grinding cycles, and can also provide a DXF converter, geometric editor, or special grinding cycles written directly by EMAG Weiss experts if needed. Users can also manually perform simple cutting or longitudinal grinding processes without using the control system. In this case, the control system is only used as a monitor for data input. These manual data can be easily transmitted to the control system through the "teach" function, in order to automatically prepare for subsequent processing of the workpiece. This can not only truly achieve the best degree of freedom for machine operation, but also quickly and easily program for simple grinding processes.

Modular machine tools suitable for all users

The versatility of the W11 CNC is not only reflected in its flexible control system, but also in the basic configuration of the machine tool itself, which is very flexible and customizable, thus meeting the needs of various users. The machine tool head frame can be equipped with spindle seats from MK 4 to MK 6, with a maximum speed of 1000 rpm, and of course, there are various fixtures available for selection. The tailstock, which can be operated by a foot switch, is equipped with an MK 4 support, resulting in a clamping force of 250 kg between the tips. The core component of the machine tool is a precision spindle grinding head with a power of up to 11 kW, which can be equipped with grinding wheels with a maximum diameter of 500 mm and a maximum width of 120 mm. Here, multiple options can also be provided for self configuration, such as grinding wheel linear speed or GAP monitoring. Not only that, the grinding head can also be equipped with a stepless programming B-axis to further improve the versatility of the machine tool.

Stainless steel cnc machining parts China Metal Parts Services - CNC Machining Parts Supplier

World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

Stainless steel cnc machining parts China Metal Parts Services - CNC Machining Parts Supplier

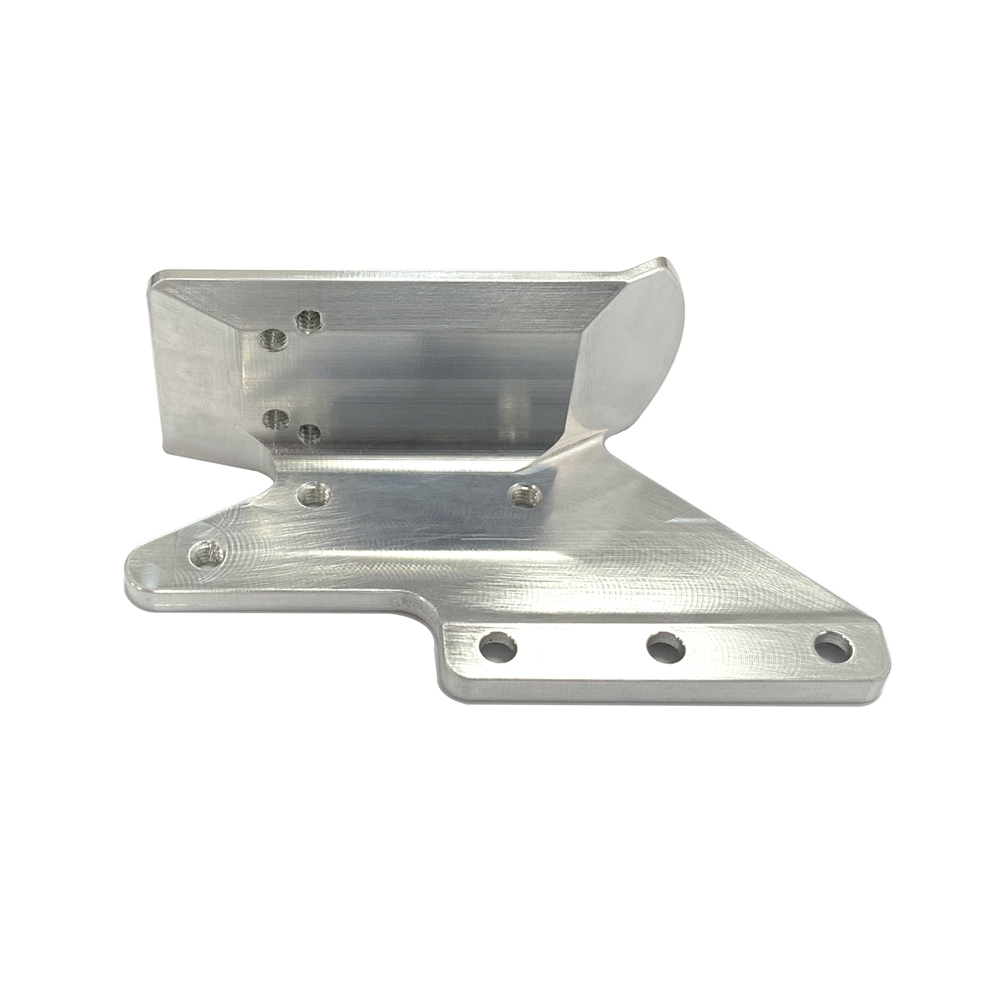

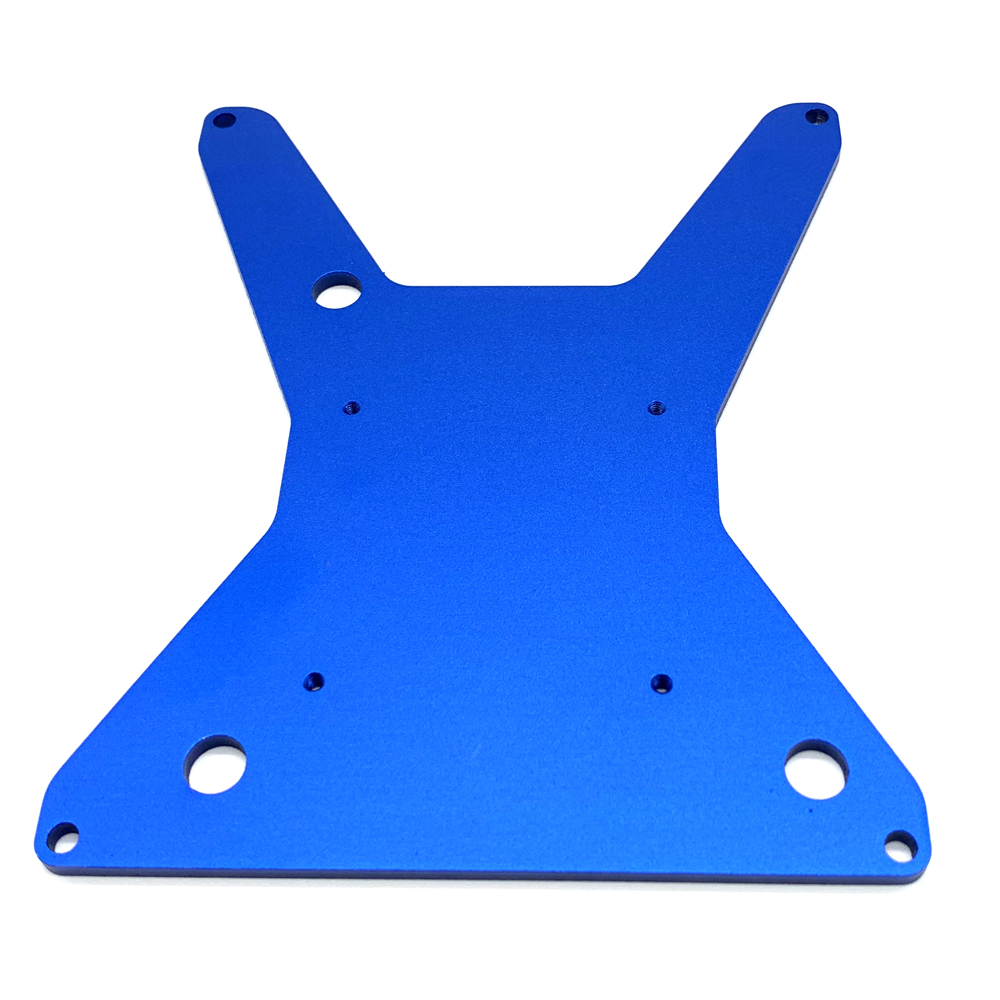

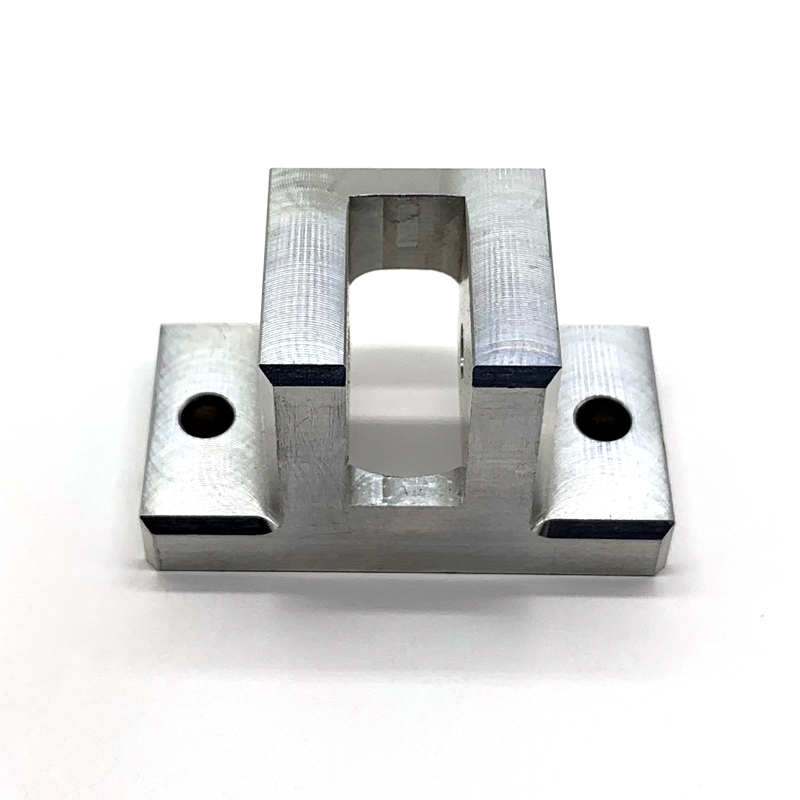

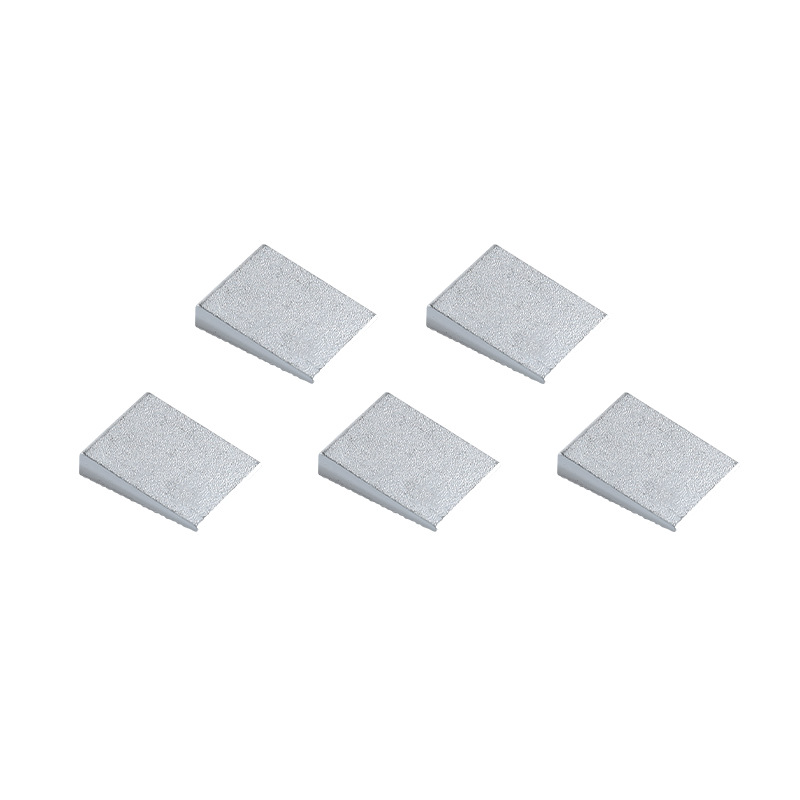

World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  customized metal board cnc parts OEM Custom Cnc Milling Turning Stainless Steel Aluminum Brass Metal Parts More

customized metal board cnc parts OEM Custom Cnc Milling Turning Stainless Steel Aluminum Brass Metal Parts More  electric motorcycle cnc milling turning metal parts Custom CNC turning milling machining aluminum service More

electric motorcycle cnc milling turning metal parts Custom CNC turning milling machining aluminum service More  Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories More

Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories Precision Cnc Turning Milling Machining Atv/Utv Parts & Accessories More  the head of custom spray gun Custom CNC Machining Service Precision Titanium Brass Stainless Steel More

the head of custom spray gun Custom CNC Machining Service Precision Titanium Brass Stainless Steel More  CNC Machining Parts Manufacturer Stainless Steel Aluminum CNC Mechanical Parts Precision CNC Turning Steel Parts ,CNC Machine Part More

CNC Machining Parts Manufacturer Stainless Steel Aluminum CNC Mechanical Parts Precision CNC Turning Steel Parts ,CNC Machine Part More  cnc milling machining turning spare parts mechanical parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

cnc milling machining turning spare parts mechanical parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  CNC Machining Precision Parts Full Shift Switch Invisible Switch China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

CNC Machining Precision Parts Full Shift Switch Invisible Switch China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  CNC machining small aluminum machined metal wheel gear parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More

CNC machining small aluminum machined metal wheel gear parts China Metal Parts Services - CNC Machining Parts Supplier World Class Quality Products with Competitive Global Pricing and On-Time Delivery. OEM/ODM Manufacturing by Self-Owned ISO 9001 Certified Factory. Send Enquiry Now! More  the customized metal parts of toy model car wheel hub we are specialized in prodicing all kinds of metal parts applying to building Material Shops, Manufacturing plant, and so forth so on More

the customized metal parts of toy model car wheel hub we are specialized in prodicing all kinds of metal parts applying to building Material Shops, Manufacturing plant, and so forth so on More  High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service We provide CNC drilling services that can process small and large batches of components of any complexity. We use different types of drilling machines (vertical, bench, radial) to drill holes with a diameter of up to 7 centimeters, and can achieve simple or complex patterns. This manufacturing method is applicable to metals and alloys (aluminum, steel, copper, etc.) and polymers More

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service We provide CNC drilling services that can process small and large batches of components of any complexity. We use different types of drilling machines (vertical, bench, radial) to drill holes with a diameter of up to 7 centimeters, and can achieve simple or complex patterns. This manufacturing method is applicable to metals and alloys (aluminum, steel, copper, etc.) and polymers More  High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service china manufacturer professional made precision profile aluminum swiss machining cnc drilling parts More

High Precision Parts Cnc Turning Machining Aluminum OEM ODM CNC Drilling Milling Machining Service china manufacturer professional made precision profile aluminum swiss machining cnc drilling parts More  Customized Pen Shell we provide CNC machining service,just sending us a drawing for quote. More

Customized Pen Shell we provide CNC machining service,just sending us a drawing for quote. More  the shell of portable battery ,the customized metal housing sent us the drawings and we give you a appropriate quote More

the shell of portable battery ,the customized metal housing sent us the drawings and we give you a appropriate quote More  the metal cap of pen ,none-standard cap we are chinese manufacturer ,we provide competetive price.we can produce CNC parts and make a polishing. More

the metal cap of pen ,none-standard cap we are chinese manufacturer ,we provide competetive price.we can produce CNC parts and make a polishing. More  What principles should be followed in the arrangement of CNC machining sequence? More

What principles should be followed in the arrangement of CNC machining sequence? More  Technology Application For CNC More

Technology Application For CNC More  Basic composition of CNC lathe More

Basic composition of CNC lathe More  Selection principles for CNC More

Selection principles for CNC More  The Fetures Of CNC More

The Fetures Of CNC More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More  CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More

CNC MACHINING SERVICE-PROCESSING MACHINERY FEATURES More